MMP DAR

This specifies the configuration for Mobile Manipulation Platform (MMP) Dual ARM Ridgeback (DAR) version running ROS2 Jazzy. It features dual xARM850 manipulators with Robotiq 2F-140 grippers, a custom 3-axis rig system, Ouster 3D lidar, dual Hokuyo lidars, Intel RealSense and ZED2i cameras.

Important

Carefully review this document. If there are uncertainties, it is crucial to seek guidance from specialists, experts, or the manufacturers of the assemblies employed. The robot should not be activated until clarification is obtained. If any doubts persist, refer to the provided guides or get in touch with a specialist, expert, or the manufacturer of the assemblies used.

Warning

The robot supplied by MYBOTSHOP GmbH is intended for research and development purposes and does not bear the CE Marking and/or Certificate of Incorporation. A fundamental understanding of ROS2 (Robot Operating System 2) is necessary. If you lack familiarity with ROS2, we recommend consulting the ROS2 Documentation as a first step.

It is important to note that the mentioned robot is categorized as a partially completed machine according to the Machinery Directive 2006/42/EC and does not carry a CE marking.

Getting Started

For powering on and basic usage of the Ridgeback base, refer to the Clearpath Ridgeback documentation.

Data Sheets

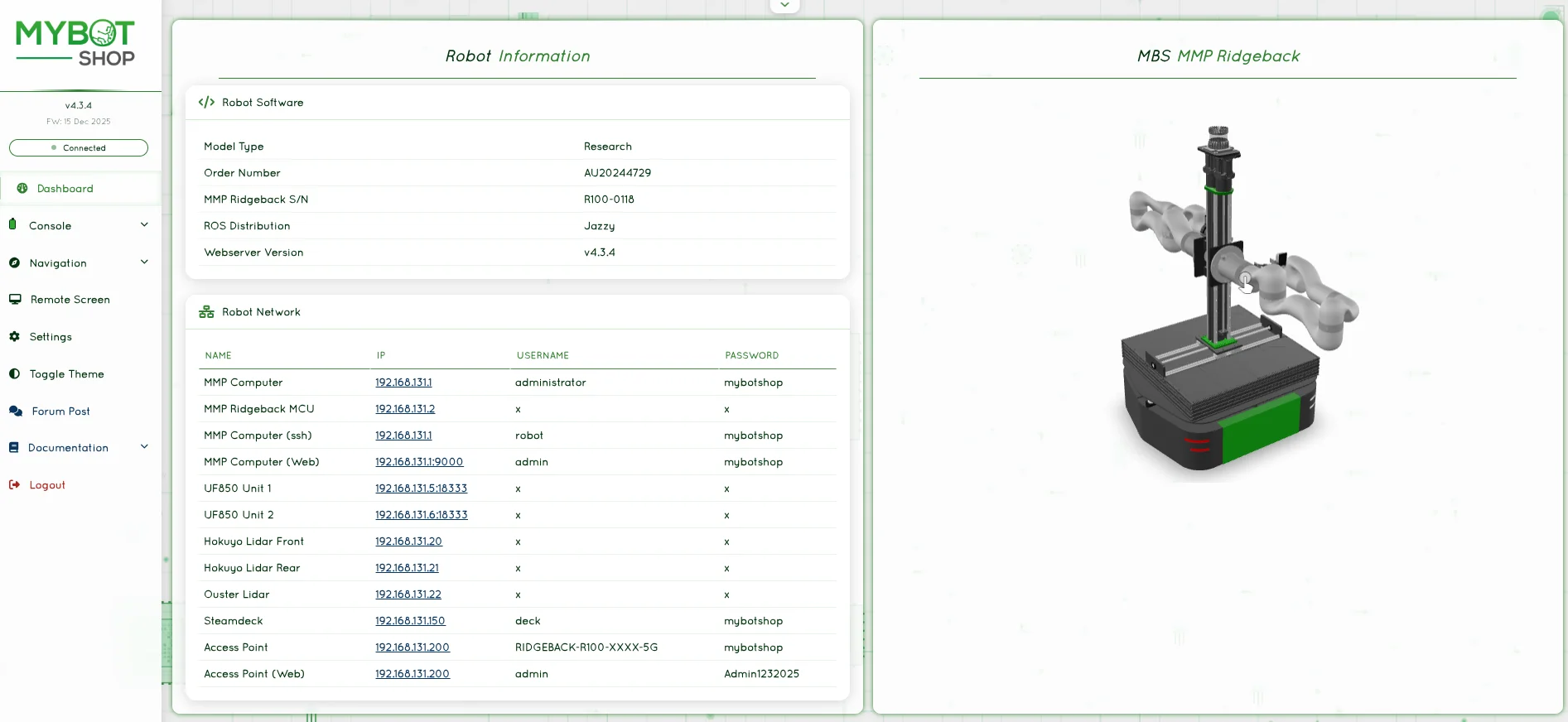

Network Setup

Device |

Network Address |

Username |

Password |

|---|---|---|---|

R100 Computer |

192.168.131.1 |

robot |

mybotshop |

R100 MCU |

192.168.131.2 |

N/A |

N/A |

Webserver |

192.168.131.1:9000 |

admin |

mybotshop |

Cockpit |

192.168.131.1:9090 |

robot |

mybotshop |

Left xARM850 |

192.168.131.5:18333 |

N/A |

N/A |

Right xARM850 |

192.168.131.6:18333 |

N/A |

N/A |

Hokuyo Front |

192.168.131.21 |

N/A |

N/A |

Hokuyo Rear |

192.168.131.22 |

N/A |

N/A |

Ouster Lidar |

192.168.131.30 |

N/A |

N/A |

Router |

192.168.131.200 |

SSID |

mybotshop |

Quick Start ROS2

Power On

Release the emergency stop button by turning it clockwise.

Press the power button to turn on the robot.

Wait for the robot to boot up completely (approximately 1-2 minutes).

The Clearpath and MMP services will start automatically.

Verify the webserver is accessible at http://192.168.131.1:9000.

Power Off

Warning

Always follow the proper shutdown procedure to prevent data corruption and hardware damage.

Deactivate the rig system (if active):

ros2 service call /r100_0118/mmp_rig/activation \

mmp_interface/srv/RigActivation \

"{base_plate: false, left_plate: false, right_plate: false}"

Disable xARM850 arms via the web interface or stop the driver services:

sudo systemctl stop mmp-xarm-driver-left.service

sudo systemctl stop mmp-xarm-driver-right.service

Engage the emergency stop by pressing it down.

Disconnect battery from Arms by clicking the red button.

Shutdown the robot via SSH or Cockpit terminal:

sudo shutdown now

Turn off the main power switch on the back of the Ridgeback.

Network Connection

Connect to the robot’s WiFi network or via Ethernet.

The robot IP address is 192.168.131.1.

The WiFi password is mybotshop.

Access the webserver at 192.168.131.1:9000.

The webserver username is admin and password is mybotshop.

SSH Connection

ssh robot@192.168.131.1

Check Service Status

sudo systemctl status clearpath-robot.service

sudo systemctl status mmp-webserver.service

Teleoperation

Teleoperate using the keyboard teleop package:

ros2 run teleop_twist_keyboard teleop_twist_keyboard \

--ros-args --remap cmd_vel:=/r100_0118/cmd_vel \

--ros-args -p stamped:=true

Note

Replace r100_0118 with your robot’s namespace. Reduce speed by pressing z until 0.1 for safe indoor operation.

Visualization

View the robot state in RViz2:

ros2 launch mmp_viz view_robot.launch.py

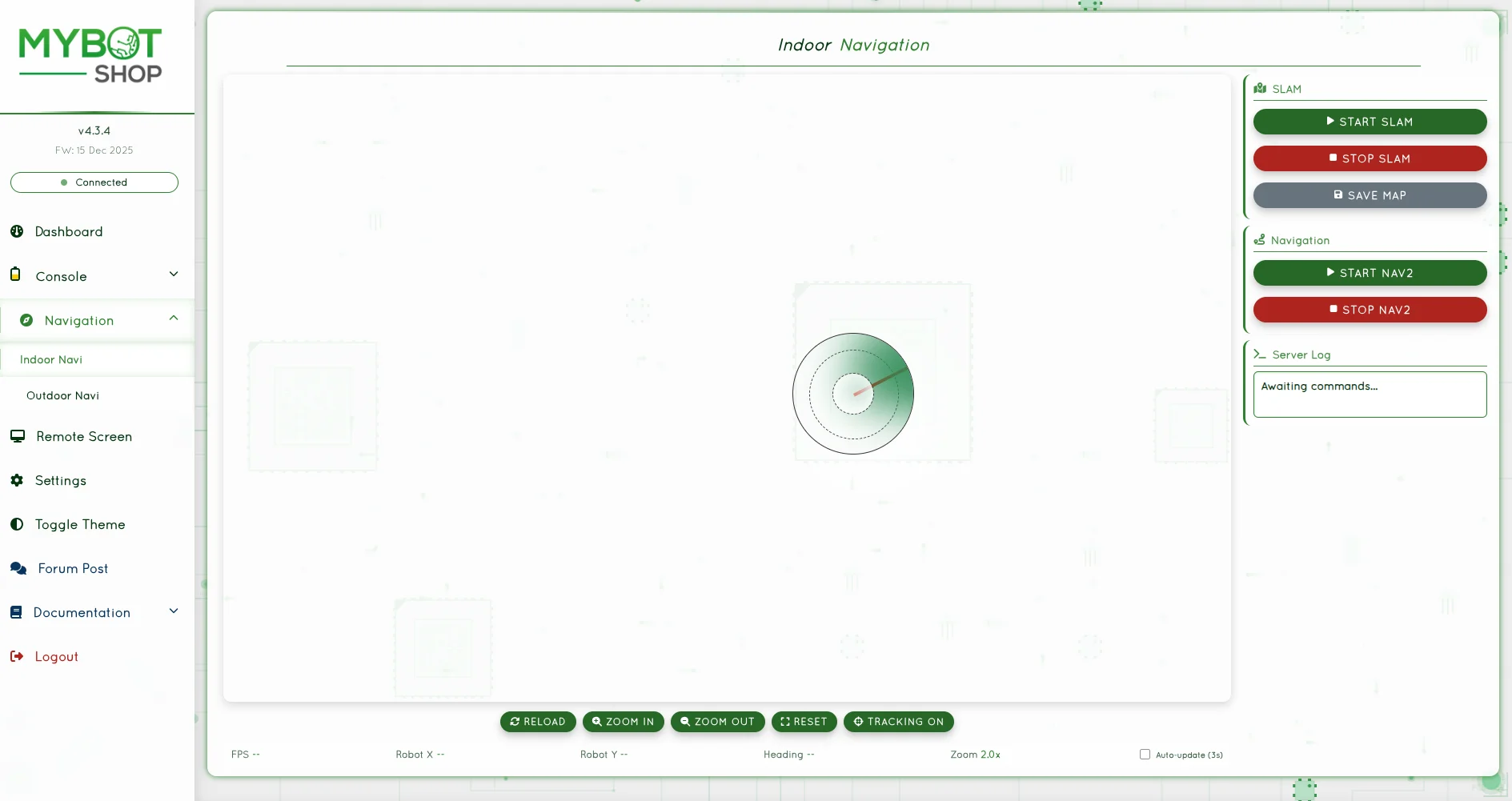

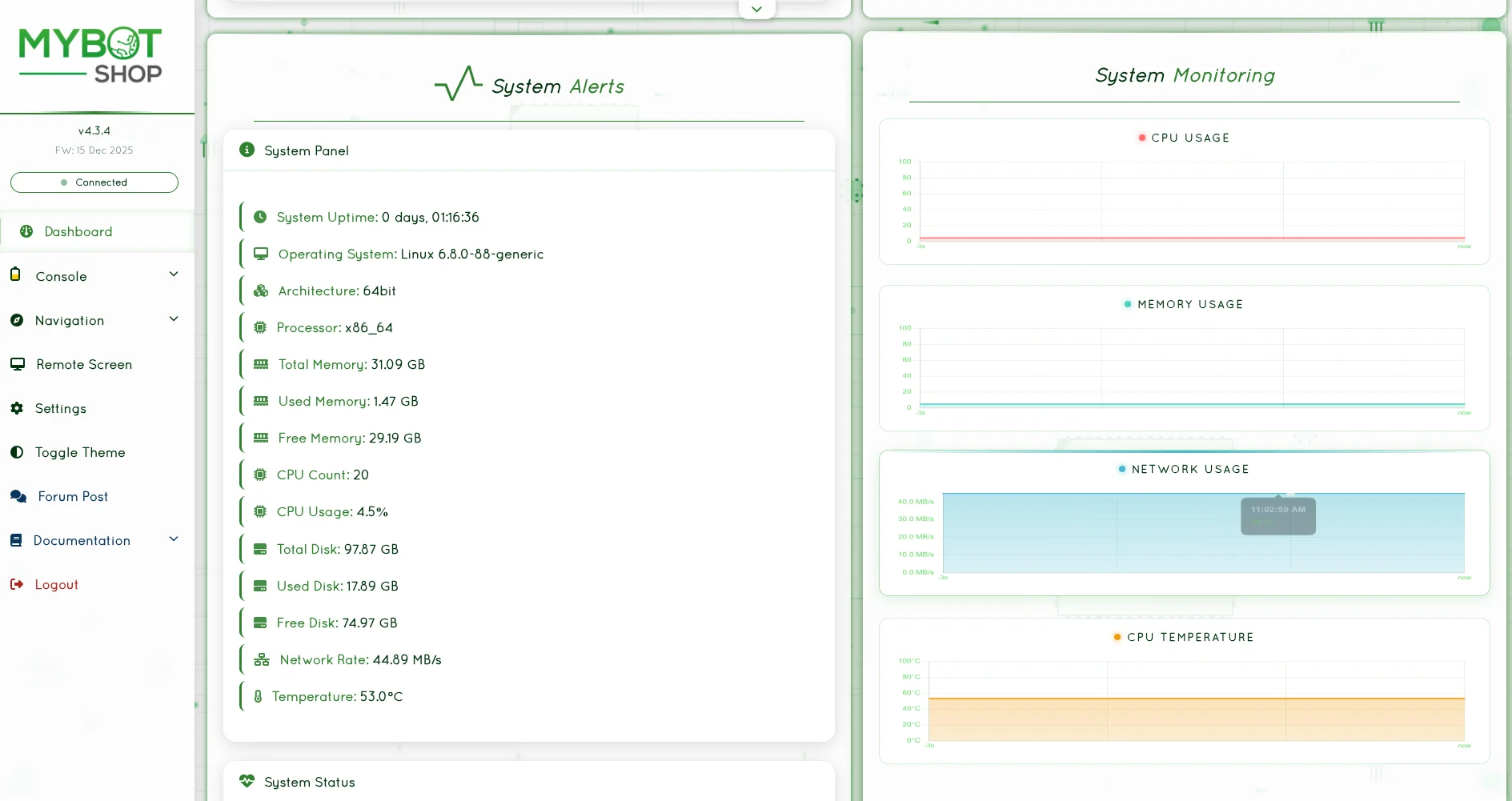

Webserver

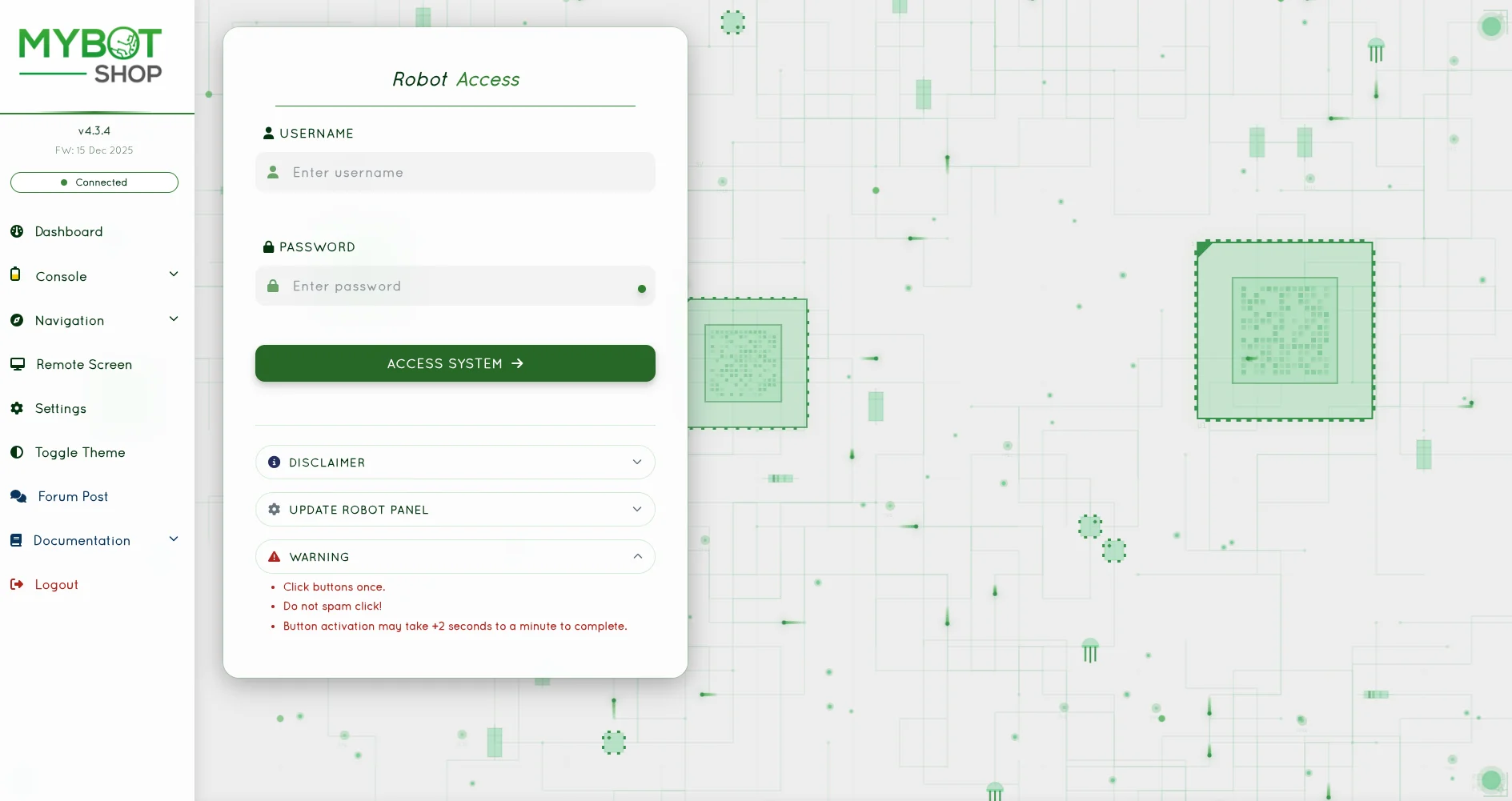

The webserver module comes pre-installed and should be accessible directly at http://192.168.131.1:9000/ or via the WiFi IP to which the robot is connected.

Login

Username: admin

Password: mybotshop

Dashboard

View IP Address of the R100

View System load

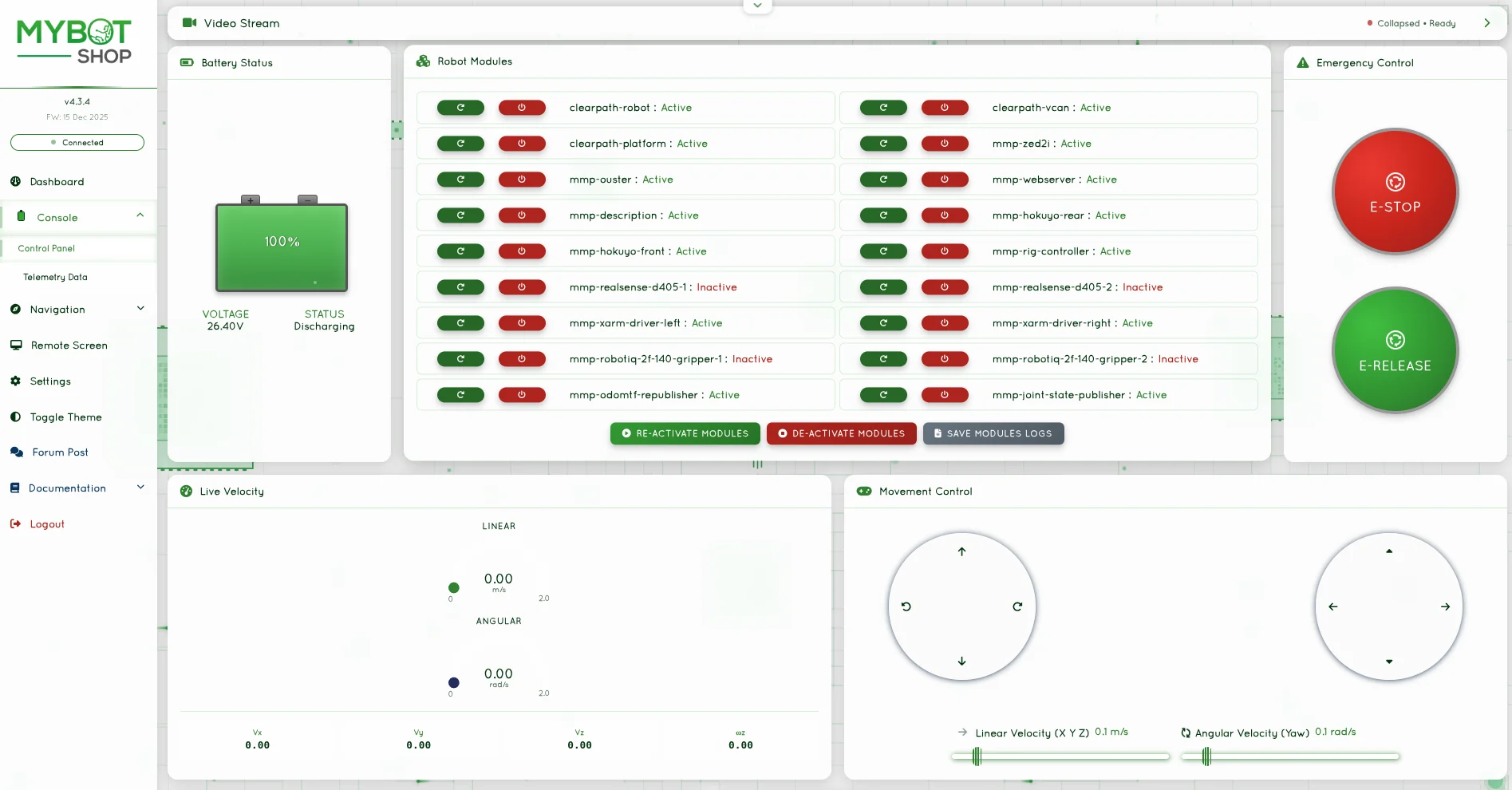

Console

Enable/Disable the R100 ROS2 Services

Record System logs

Battery status monitoring

Pre-configured action buttons (adaptable to new ROS2 services)

Web Joystick for teleoperation

Online image stream

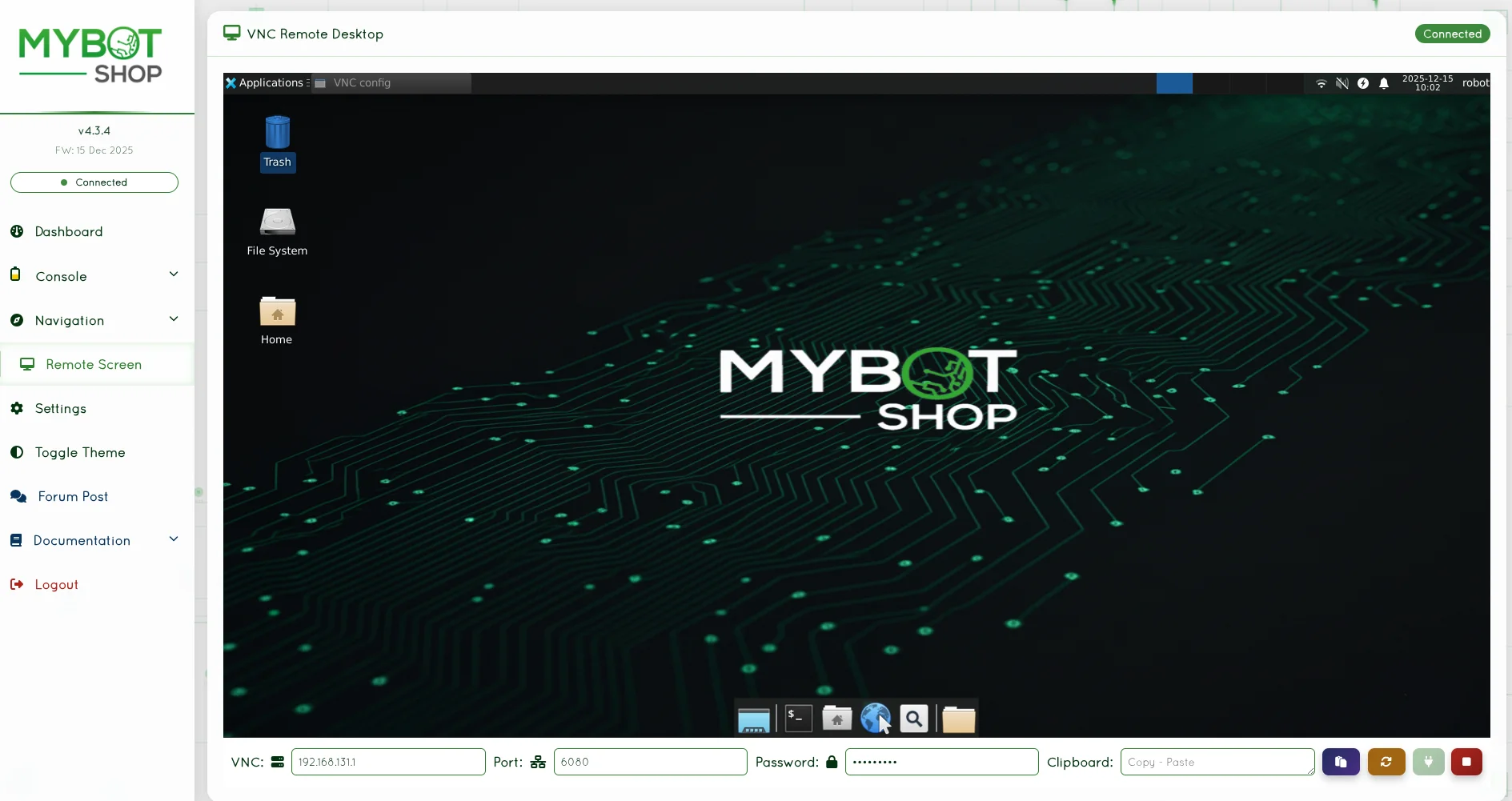

Remote Desktop (VNC)

Access on-board screen of the R100’s computer:

ROS2 Package Reference

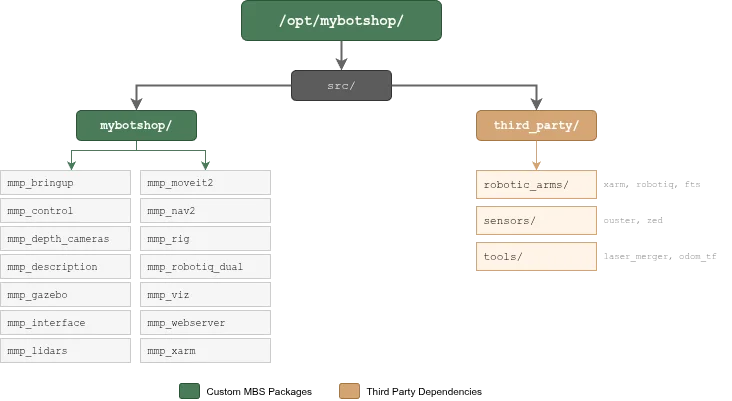

Workspace Structure

The MMP R100 workspace is organized into two main categories: mybotshop (custom MBS packages) and third_party (external dependencies).

mybotshop Packages

Package |

Description |

|---|---|

mmp_bringup |

System startup and service management |

mmp_control |

Base and manipulator controllers |

mmp_depth_cameras |

RealSense and ZED camera drivers |

mmp_description |

URDF/Xacro robot models |

mmp_dual_uf850_moveit2 |

Dual arm MoveIt2 configuration |

mmp_gazebo |

Gazebo Fortress simulation |

mmp_interface |

Custom messages and services |

mmp_lidars |

Hokuyo and Ouster LiDAR drivers |

mmp_nav2 |

Nav2 navigation stack configuration |

mmp_rig |

3-axis linear actuator control |

mmp_robotiq_dual |

Dual Robotiq 2F-140 gripper control |

mmp_viz |

RViz2 visualization configurations |

mmp_webserver |

Web dashboard and remote control |

mmp_xarm |

Dual xARM850 driver configuration |

third_party Dependencies

Category |

Package |

Description |

|---|---|---|

robotic_arms |

xarm_ros2 |

UFactory xArm drivers |

robotic_arms |

robotiq_gripper_ros2 |

Robotiq gripper drivers |

robotic_arms |

rq_fts_ros2 |

Robotiq FT sensor drivers |

sensors |

ouster-ros |

Ouster OS1 LiDAR driver |

sensors |

zed_ros2 |

Stereolabs ZED2i driver |

tools |

ros2_laser_scan_merger |

Multi-LiDAR scan fusion |

tools |

odom_to_tf_ros2 |

Odometry to TF publisher |

Emergency Stop (E-Stop)

Warning

The Emergency Stop (E-Stop) is a critical safety mechanism. When activated, it immediately halts all motion on ALL connected systems.

E-Stop Connected Systems

The E-Stop circuit is connected to and controls the following systems:

System |

Description |

|---|---|

Ridgeback Mobile Base |

Clearpath Ridgeback omnidirectional platform (disables wheels) |

Rig System - Base Plate |

Horizontal translation (Forward/Rear, 0-400mm range) |

Rig System - Left Plate |

Vertical lift for left arm (Up/Down, 0-500mm range) |

Rig System - Right Plate |

Vertical lift for right arm (Up/Down, 0-500mm range) |

Left xARM850 |

6-DOF robotic arm with Robotiq 2F-140 gripper |

Right xARM850 |

6-DOF robotic arm with Robotiq 2F-140 gripper |

E-Stop Behavior

When E-Stop is ENGAGED (pressed):

All motors on the Ridgeback cease operation immediately

All three rig axes stop and hold position (brakes engage)

Both xARM850 arms enter emergency stop state (servos disabled)

All motion commands are ignored until E-Stop is released

When E-Stop is RELEASED:

Important

Systems do NOT automatically resume operation after E-Stop release.

Each system must be re-enabled manually:

Ridgeback: Automatically recovers when E-Stop is released

Rig System: Re-activate via service call:

ros2 service call /r100_0118/mmp_rig/activation \

mmp_interface/srv/RigActivation \

"{base_plate: true, left_plate: true, right_plate: true}"

xARM850 Arms: Re-enable via xARM web interface or driver restart

Warning

If xARM850 arms fail to start after E-Stop release and you cannot hear clicking sounds, engage E-Stop again, wait 5 seconds, release, and retry enabling the arms.

Dual xARM850 Startup

Ensure the robot arms are receiving power (flip the 50A lever towards its black counterpart).

To enable, go to console in Dashboard (http://192.168.131.1:9000) and activate the xARM driver services.

If the xARM850 doesn’t start and you can’t hear clicking sound, engage the emergency stop and release it after 5 seconds. Then try again either with the driver or their web interface at:

Left arm: http://192.168.131.5:18333

Right arm: http://192.168.131.6:18333

Rig Control

The 3-axis rig system provides positioning for the dual manipulator arms.

Rig Position Ranges

Axis |

Min |

Max |

Direction |

|---|---|---|---|

Base Plate |

0 |

400 |

0=Front, 400=Rear |

Left Plate |

0 |

500 |

0=Down, 500=Up |

Right Plate |

0 |

500 |

0=Down, 500=Up |

Activation

# Activate rig system

ros2 service call /r100_0118/mmp_rig/activation \

mmp_interface/srv/RigActivation \

"{base_plate: true, left_plate: true, right_plate: true}"

# Deactivate rig system (recommended when not in use)

ros2 service call /r100_0118/mmp_rig/activation \

mmp_interface/srv/RigActivation \

"{base_plate: false, left_plate: false, right_plate: false}"

Position Control

Warning

Ensure arms are not in collision path before moving rig!

# Move to middle + mid position

ros2 service call /r100_0118/mmp_rig/control \

mmp_interface/srv/RigControl \

"{base_plate: 200.0, left_plate: 250.0, right_plate: 250.0}"

# Move to rear + highest position

ros2 service call /r100_0118/mmp_rig/control \

mmp_interface/srv/RigControl \

"{base_plate: 400.0, left_plate: 500.0, right_plate: 500.0}"

# Move to front + lowest position

ros2 service call /r100_0118/mmp_rig/control \

mmp_interface/srv/RigControl \

"{base_plate: 0.0, left_plate: 0.0, right_plate: 0.0}"

Velocity Control

For simple velocity-based movement:

# Stop all axes

ros2 topic pub /r100_0118/mmp_rig/cmd_vel \

mmp_interface/msg/RigControlCmd \

"{base_plate: 0, left_plate: 0, right_plate: 0}"

# Move base plate forward

ros2 topic pub /r100_0118/mmp_rig/cmd_vel \

mmp_interface/msg/RigControlCmd \

"{base_plate: 1, left_plate: 0, right_plate: 0}"

Dual xARM850 Control

Key Launch Files

custom_dualarm_drivers.launch.py- Launch both arms with custom configurationinclude/xarm850_unit_1.launch.py- Left arm onlyinclude/xarm850_unit_2.launch.py- Right arm only

Configuration

Left arm IP: 192.168.131.5 (Web interface: http://192.168.131.5:18333)

Right arm IP: 192.168.131.6 (Web interface: http://192.168.131.6:18333)

MoveIt2 Configuration

MoveIt2 configuration for dual UF850 (xARM850) manipulator motion planning. Provides motion planning, collision avoidance, and coordinated dual-arm control.

Planning Groups:

left_arm- Left xARM850 planning groupright_arm- Right xARM850 planning groupdual_arm- Coordinated dual-arm planning

Usage:

# Launch dual arm MoveIt

ros2 launch mmp_dual_uf850_moveit2 mbs_dual_arm.launch.py

# Launch visualizer

ros2 launch mmp_viz view_dualarm.launch.py

Note

Configure planner with OMPL -> TRRT (default). Ensure to see trails of planned path before execution.

Test xARM Trajectory

# Make Left Robot Arm Stand

ros2 action send_goal /r100_0118_uf1/uf850_ufactory_unit01_traj_controller/follow_joint_trajectory \

control_msgs/action/FollowJointTrajectory "{

trajectory: {

joint_names: [uf_left_joint1, uf_left_joint2,

uf_left_joint3, uf_left_joint4,

uf_left_joint5, uf_left_joint6],

points: [{

positions: [-0.003, 0.424, -0.907,

-0.005, 0.241, 0.1],

time_from_start: {sec: 5, nanosec: 0}

}]

}

}"

# Make Right Robot Arm Stand

ros2 action send_goal /r100_0118_uf2/uf850_ufactory_unit02_traj_controller/follow_joint_trajectory \

control_msgs/action/FollowJointTrajectory "{

trajectory: {

joint_names: [uf_right_joint1, uf_right_joint2,

uf_right_joint3, uf_right_joint4,

uf_right_joint5, uf_right_joint6],

points: [{

positions: [-0.003, 0.424, -0.907,

-0.005, 0.241, 0.1],

time_from_start: {sec: 5, nanosec: 0}

}]

}

}"

Dual Gripper Control

Dual Robotiq 2F-140 gripper control via xArm RS485 tool port.

Key Launch Files

gripper_left.launch.py- Left gripper controllergripper_right.launch.py- Right gripper controller

Services

/r100_0118/gripper/left/open- Open left gripper/r100_0118/gripper/left/close- Close left gripper/r100_0118/gripper/left/set_position- Set left gripper position/r100_0118/gripper/left/reset- Reset left gripper(Same services available for right gripper)

Usage

# Launch gripper controllers

ros2 launch mmp_robotiq_dual gripper_left.launch.py

ros2 launch mmp_robotiq_dual gripper_right.launch.py

# Open/Close grippers via service

ros2 service call /r100_0118/gripper/left/open std_srvs/srv/Trigger

ros2 service call /r100_0118/gripper/left/close std_srvs/srv/Trigger

# Set gripper position (0=open, 255=closed)

ros2 service call /r100_0118/gripper/left/set_position \

mmp_interface/srv/GripperCommand \

"{position: 128, speed: 255, force: 100}"

# Reset gripper (use when gripper stops responding)

ros2 service call /r100_0118/gripper/left/reset std_srvs/srv/Trigger

MoveIt Action Interface

Position in radians: 0.0=open, 0.7=closed

# Open gripper fully (0.0 rad)

ros2 action send_goal \

/r100_0118/left_gripper_controller/gripper_cmd \

control_msgs/action/GripperCommand \

"{command: {position: 0.0, max_effort: 50.0}}"

# Close gripper fully (0.7 rad)

ros2 action send_goal \

/r100_0118/left_gripper_controller/gripper_cmd \

control_msgs/action/GripperCommand \

"{command: {position: 0.7, max_effort: 50.0}}"

Note

MoveIt sends position as joint angle in radians (matching URDF finger joint limits 0-0.7 rad).

Monitor Gripper Joint States

ros2 topic echo /r100_0118/robotiq_2f_140/left/joint_states

ros2 topic echo /r100_0118/robotiq_2f_140/right/joint_states

LiDAR Sensors

Key Launch Files

combined_scan.launch.py- Merges multiple LiDAR scansinclude/hokuyo_f.launch.py- Front Hokuyo UST-20LXinclude/hokuyo_r.launch.py- Rear Hokuyo UST-20LXinclude/ouster.launch.py- Ouster OS1 3D LiDAR

IP Configuration

Sensor |

IP Address |

|---|---|

Hokuyo Front |

192.168.131.21 |

Hokuyo Rear |

192.168.131.22 |

Ouster |

192.168.131.30 |

Depth Cameras

Key Launch Files

realsense_i.launch.py- First RealSense camera (D405)realsense_ii.launch.py- Second RealSense camera (D455)zed.launch.py- ZED2i stereo camera

Note

Running Ouster and RealSense simultaneously may cause camera latency due to high bandwidth usage. Consider using one or the other for optimal performance.

Simulation

The R100 simulation package uses ROS2 Jazzy with Gazebo Fortress, featuring the complete MMP platform with dual xArm850 arms, Robotiq grippers, FT300 sensors, and adjustable rig on a Clearpath Ridgeback base.

Prerequisites

ROS 2 Jazzy

Gazebo Fortress

gz_ros2_control

Clearpath robot packages

Launch Simulation

export ROS_LOCALHOST_ONLY=1

source /opt/ros/jazzy/setup.bash

source /opt/mybotshop/install/setup.bash

ros2 launch mmp_gazebo simulation.launch.py

To kill Gazebo zombie processes:

ros2 run mmp_gazebo kill_gz.sh

Environment Variables

Configure the simulation using environment variables before launch:

Variable |

Default |

Description |

|---|---|---|

MMP_RIDGEBACK_GAZEBO |

1 |

Enable Gazebo simulation mode |

MMP_RIDGEBACK_RIG |

1 |

Include rig (tower + brackets) |

MMP_RIG_PLATE_JOINTS |

1 |

Enable rig joint control |

MMP_RIDGEBACK_XARM850 |

1 |

Include dual xArm850 arms |

MMP_RIDGEBACK_OUSTER |

0 |

Include Ouster lidar |

MMP_RIDGEBACK_ZED |

0 |

Include ZED2i camera |

MMP_RIDGEBACK_FT |

1 |

Include Robotiq FT300 sensors |

MMP_RIDGEBACK_GRIPPER |

1 |

Include Robotiq 2F-140 grippers |

MMP_RIDGEBACK_GRIPPER_D405 |

0 |

Include Intel D405 cameras |

Available Controllers

Controller |

Description |

|---|---|

joint_state_broadcaster |

Publishes joint states |

platform_velocity_controller |

Base movement (4 wheels) |

uf_left_arm_controller |

Left xArm850 (6 joints) |

uf_right_arm_controller |

Right xArm850 (6 joints) |

rig_position_controller |

Tower + brackets (3 joints) |

uf_left_gripper_controller |

Left Robotiq 2F-140 |

uf_right_gripper_controller |

Right Robotiq 2F-140 |

Check controllers:

ros2 control list_controllers -c /r100_0118/controller_manager

RViz2 Visualization

ros2 launch mmp_viz view_robot.launch.py

Teleoperation (Keyboard)

ros2 run teleop_twist_keyboard teleop_twist_keyboard \

--ros-args --remap cmd_vel:=/r100_0118/cmd_vel \

--ros-args -p stamped:=true

Move Arms in Simulation

# Move left arm

ros2 action send_goal \

/r100_0118/uf_left_arm_controller/follow_joint_trajectory \

control_msgs/action/FollowJointTrajectory "{

trajectory: {

joint_names: [uf_left_joint1, uf_left_joint2,

uf_left_joint3, uf_left_joint4,

uf_left_joint5, uf_left_joint6],

points: [{

positions: [-1.57, 1.57, 0.0, 0.5, 0.0, 0.0],

time_from_start: {sec: 2}

}]

}

}"

Move Rig in Simulation

# Raise tower and extend brackets

ros2 action send_goal \

/r100_0118/rig_position_controller/follow_joint_trajectory \

control_msgs/action/FollowJointTrajectory "{

trajectory: {

joint_names: [ridgeback_tower_xarm850_joint,

ridgeback_xarm850_bracket_left_joint,

ridgeback_xarm850_bracket_right_joint],

points: [{

positions: [0.2, 0.3, 0.3],

time_from_start: {sec: 2}

}]

}

}"

Control Grippers in Simulation

# Open left gripper (0.0 = open)

ros2 action send_goal \

/r100_0118/uf_left_gripper_controller/gripper_cmd \

control_msgs/action/GripperCommand \

"{command: {position: 0.0, max_effort: 100.0}}"

# Close left gripper (0.695 = closed)

ros2 action send_goal \

/r100_0118/uf_left_gripper_controller/gripper_cmd \

control_msgs/action/GripperCommand \

"{command: {position: 0.695, max_effort: 100.0}}"

Installation

ROS2 Jazzy Fresh Installation

Install ROS Jazzy and Clearpath packages:

sudo apt-get install ros-jazzy-clearpath-* -y

sudo apt update && sudo apt upgrade

Run the Clearpath computer installer script:

cd mbs_ridgeback/src/mybotshop/mmp_bringup/scripts

bash clearpath_computer_installer.sh

Add R100 Ridgeback when prompted.

Start the Clearpath service:

sudo systemctl daemon-reload

sudo systemctl start clearpath-robot.service

Create the mybotshop workspace directory:

sudo mkdir /opt/mybotshop

sudo chown -R robot:robot /opt/mybotshop

sudo chown -R robot:robot /etc/clearpath

Copy the workspace to

/opt/mybotshop/and run the dependency installer:

cd /opt/mybotshop/src

./ros2_dependencies

Build the workspace:

cd /opt/mybotshop

colcon build --symlink-install \

--cmake-args -DCMAKE_BUILD_TYPE=Release

source install/setup.bash

Install custom sensor services:

ros2 run mmp_bringup startup_installer.py

Disable system suspend:

sudo systemctl mask sleep.target suspend.target \

hibernate.target hybrid-sleep.target

Sync Host Computer to Robot

To sync your development workspace to the robot:

rsync -avP -t --delete -e ssh src \

administrator@192.168.131.1://opt/mybotshop

Caution

Always remain close to the emergency stop buttons.

Power off the robot correctly via the proper shutdown procedure.

Sudden jerks to the mobile robot can cause a disconnection. The velocity provided should always be smooth.

Ensure arms are not in collision path before moving the rig system.

Known Issues

xARM850 not starting:

If the xARM850 doesn’t start and you can’t hear clicking sounds, engage the emergency stop and release it after 5 seconds. Then try again.

Camera latency:

Running Ouster and RealSense simultaneously may cause latency. Consider using one or the other for optimal performance.

Safety Guidelines

For comprehensive safety guidelines regarding robotic manipulators and autonomous mobile robots, please refer to the Robotic Manipulator Safety section.